Welcome back to my blog. Today I will give you some great beginner blacksmith things to make that will help you learn some useful skills.

When I joined the Badger Blacksmiths club I took a beginner class where we were taught some good beginner tools and techniques to practice. To get better at blacksmithing you have to learn things like round and flat tapering, scrolling, splitting, bending, twisting, rounding, and punching (not with your fists).

Tapering

For square tapering, start on the very end of the piece hitting the top side then a 45° turn to the side. Hit there then turn it to the side you turned from going up untell you are satisfied.

To make a round tapper take the square tapper and nock down the corners to make it an octagon. Then take the corners down then just tapping in a circle.

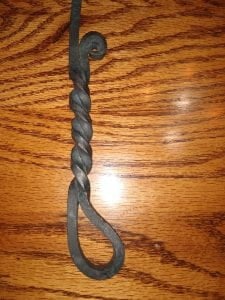

Scrolling

When you are making a scroll, you do the same thing with the tapper except you don’t do the 45° turn you just straighten. Once you are happy with the length, you put a little bit over the edge, tapping down and going forward so it makes a U shape. Tap the end until it looks like a curl and keep slightly tapping the back of the curl to continue it to your desired size.

If you only use half of the scroll you can make a coat hook (this is also known as bending). You’ll need to do a bit of flattening for the upper part of the coat hook.

Splitting

Splitting is pretty easy (except for the fact that you need a specific tool, a splitter/ hot cut which is a piece of metal that is a tapper brought to a sharp point for you to cut with). To start your cut, you just set your hot cut tool where you need to cut and just hit the back until you cut as far as you need (make sure to cool your tools so they don’t lose their temper).

You can use this skill to make many things like tongs or two-sided coat hooks with one screw plate.

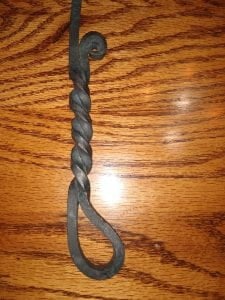

Twisting

It is pretty straight forward. Take the piece you want to twist (I recommend a square piece because it looks more professional) and grab one end with a leg vise and the other with a wrench. Twist until you are happy.

If you want to twist two ends of a piece together you can make a great handle by grabbing both of the ends you want to twist.

Punching

To make a hole in a piece, you can take a punch and drive it through the piece to make the hole a satisfactory size (I recommend punching from both sides to make it even).

I hope this post will help you get better at honing your craft. Happy reading from this backyard blacksmith.

Then put the kale wool down around the rest of the inside of the tank painting the refractory on top. Smoothen it out, making sure the hole for the gas to go through is open and protected.

Then put the kale wool down around the rest of the inside of the tank painting the refractory on top. Smoothen it out, making sure the hole for the gas to go through is open and protected.

Connect the tubing to the pipe with a valve.

Connect the tubing to the pipe with a valve.